Thoughts on aseptic process simulation

Robotic filling lines within gloveless isolators

Produktion

Abstract

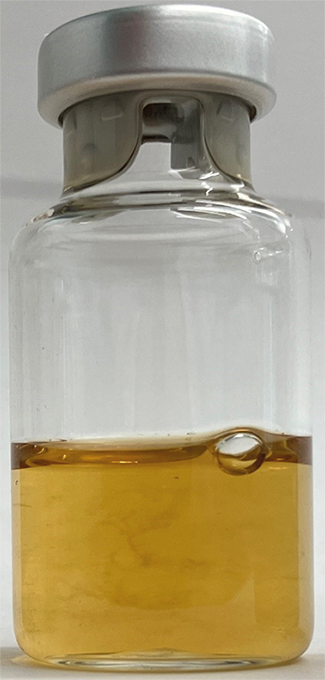

One of the main goals during aseptic production of drug products is to avoid contamination. As requirements from health authorities on processes and manufacturers increase, so do the technical possibilities to meet these demands. This includes the use of robotics and gloveless isolators in the aseptic filling of sterile drug products. At the same time, current requirements apply to such filling lines. However, directly transferring today's procedures to robotic filling lines is not feasible.

This article aims to explore the differences between conventional and robotic filling lines concerning aseptic process simulations for liquid drug products. It highlights relevant differences and possible procedures for aseptic process simulation. Based on this analysis, rationales and processes for the practical planning and execution of an aseptic process simulation on a robotic filling line within a gloveless isolator are proposed.

Correspondence:

Dennis Dürr

Roche Diagnostics GmbH, Sandhofer Straße 116, 68305 Mannheim

dennis.duerr@roche.com

| Dennis Dürr has been working at Roche in Mannheim since 2010. He completed an apprenticeship as a chemical laboratory worker, a Bachelor Professional of Pharmaceutical Production and Management (CCI), and a B. Sc. in Industrial Pharmacy. His experience includes roles as a chemical lab worker, foreman in pharmaceutical packaging inspection, team lead in insulin delivery system packaging, and currently as a process validation expert focusing on aseptic process simulations. |

Abstract

One of the main goals during aseptic production of drug

Schließen Sie hier ein Abonnement ab und profitieren Sie von den vielseitigen Nutzungsmöglichkeiten.